We’re going to take a trip back, way back, to where our journey began.

In 2016 our world seemed unexciting and small. Together we devised a master plan to literally get away from it all.

We docked in Rome, found a youth hostel and had some money to spare.

When we returned home after being wined and dined, our sunglasses still

held their appeal, so we said, “It’s sunglasses we will make!”

Making sunglasses was undeniably our calling, our joint destiny, our fate.

We were rich in spirit, but our accountant said, “My numbers say you’re poor.” Each morning we got up early. At 8:00 a.m. we donned suit and tie.

Today, DE® is the realization of our early dream.

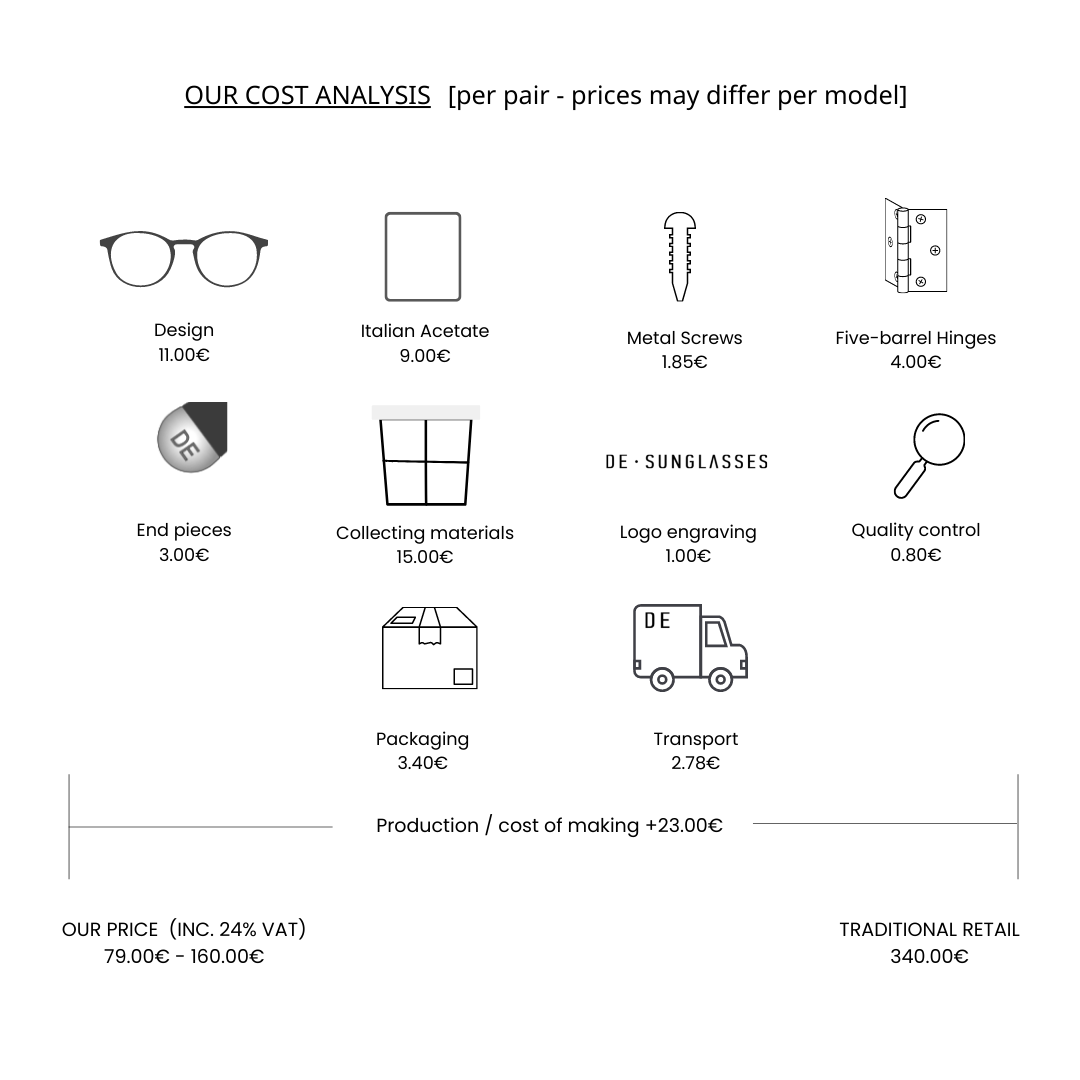

WHAT MAKES OUR EYEWEAR SPECIAL

Literally, everything. Back in 2016, when we launched our company, we were one of the first companies in the global market that made high-quality products at affordable prices. The sunglasses we produce are 100% handmade with the best materials. We have always focused on classic silhouettes with a dash of modern touches. However, we are intrigued to create a fashion trend wave the first chance we get, whatever that entails. The love for our work and the high quality of our products made us famous all over the world.

OUR LENSES PROTECTION

De-sunglasses' s lenses provide UV400 protection. They provide complete protection from the ultraviolet rays of the sun.

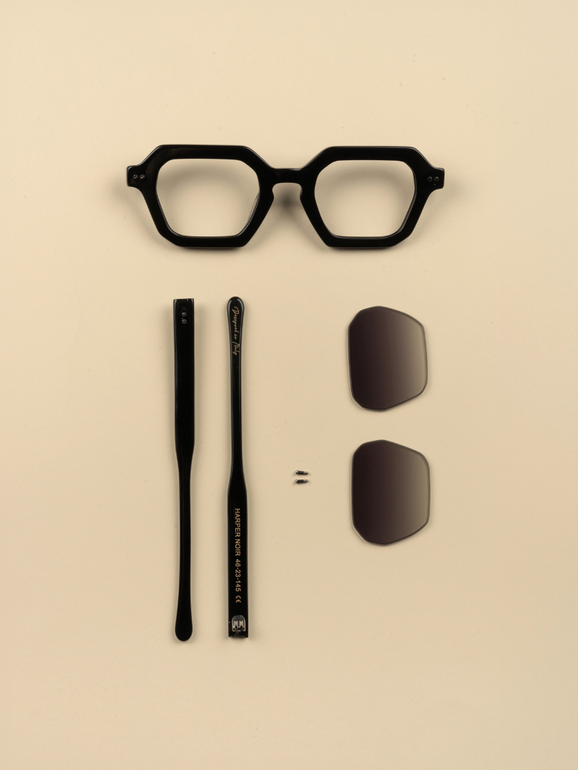

OUR MATERIALS

As you may already know, all of our products are 100% handmade. From the design to the selection of the materials till the final result. We choose the best materials in order to have the perfect result for your eyes, keeping in mind that your and our eyes are irreplaceable. We use Italian Acetate or Metal depending on the model, and mostly CR-39 lenses which are super durable.

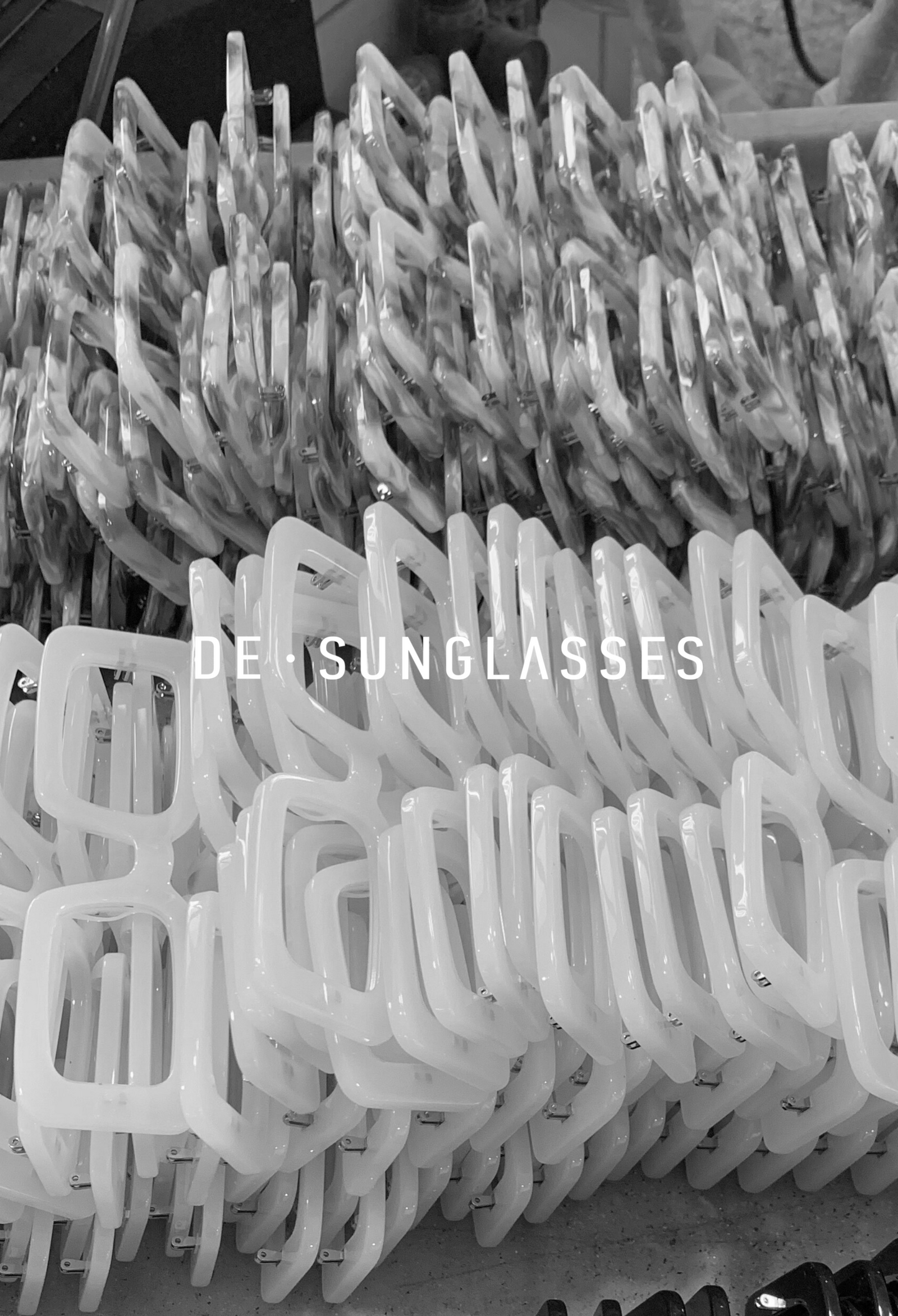

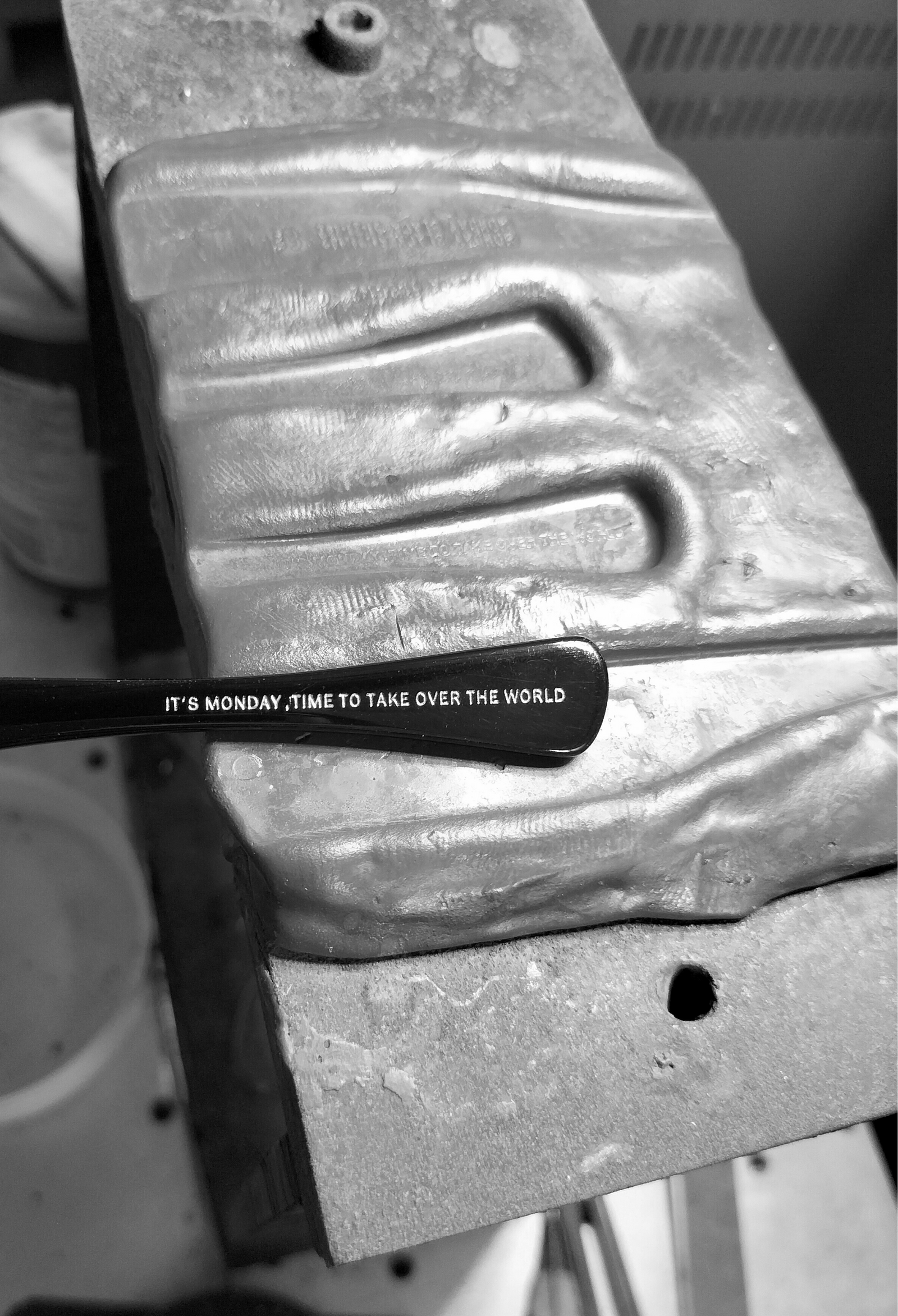

THE FACTORY

We only trust family-owned factories.We have visited every single one of our manufacturers and have met the owners. This way we ensure that the workplace is well-kept, safe, and treats their workers well.

OUR LENSES PROTECTION

De-sunglasses' s lenses provide UV400 protection. They provide complete protection from the ultraviolet rays of the sun.

THE FACTORY

We only trust family-owned factories.We have visited every single one of our manufacturers and have met the owners. This way we ensure that the workplace is well-kept, safe, and treats their workers well.

Our mission: Revolutionizing the optical industry: We are your new standard in transparency and sustainability.

OUR MISSION

Revolutionizing the optical industry: We are your new standard in transparency and sustainability.

OUR PROMISE

We respect the environment we live in and we are constantly taking steps to uphold this attitude, so all of our products are cruelty-free and vegan! The acetate we use is plant-based, our cases are made of faux leather and the packaging of our products including the customer cards comes from recycled materials. With small steps at the time, we can all make a difference. There is no planet B.

WHAT MAKES US DIFFERENT

100% Handmade SunglassesWe produce the sunglasses at our own factory department right after the designs are completed.The process takes 90 days.

A LITTLE BIT MORE OF

The backstage

Worth seeing...